Description

Applications

- For use in IEC governed hazardous areas. Polyamide is not recognized for use in any NEC/CEC governed hazardous areas.

- Local control stations and motor control stations for use in hazardous areas covering the broadest possible range of

applications.

- Control of equipment at:

— Power plants

— Chemical and petrochemical plants

— Petroleum refineries

— Reverse osmosis plants

— Pulp and paper processing plants

— Various industrial applications

- Push buttons and selector switches are used in conjunction with contactors or magnetic starters for remote control of

motors in hazardous locations. They provide circuit control and/or selection.

- Pilot lights provide visual assurance that an electrical function is being performed at a remote or hazardous location.

- For use in washdown areas.

Features

- Employs Ex de method of protection which eliminates the need for external seals.

- Operators include push buttons, illuminated push buttons, selector switches, control and load break switches and LED

pilot lights.

- Pilot light employs high intensity single LED with lifetime of 100,000 hours that can be used at:

— 12 Vac to 254 Vac 50/60 Hz

— 12 Vdc to 60 Vdc

- Up to 3 contact blocks per actuator can be used.

- Contact block technical data:

— IEC rated operating voltage (Ue): 500 Vac – 110 Vdc

— IEC switching capacity:

– AC12: 16 Amp/400 Vac

– AC14: 10 Amp/400 Vac

– AC15: 6 Amp/500 Vac

– DC13: 2 Amp/24 Vdc and 1 Amp/110 Vdc

— NEMA switching capacity: A600: 10 Amp/600 Vac

- Selector switch technical data:

— IEC rated operating voltage: 690 Vac

— IEC rated operating current: maximum 16 Amp

— IEC switching capacity:

– AC1: 16 Amp/690 Vac

– AC15: 16 Amp/415 Vac

– AC3: 8 Amp/500 Vac

– AC3: 4 Amp/690 Vac

– AC3: 16 Amp/690 Vac

– DC1: 10 Amp/24 Vdc

– DC1: 6 Amp/60 Vdc

– DC1: 6 Amp/110 Vdc (2 contacts wired in series)

– DC1: 6 Amp/220 Vdc (3 contacts in series)

— NEMA switching capacity: A600: 10 Amp/600 Vac

- Enclosures are rated for IP66 with firmly secured gasket.

- Operators and contact blocks are spaced for easy wiring.

- Wide selection of termination methods available.

- Choice of DIN rail mounted high performance contact block suitable for low intensity (less than 5 mA).

- TS35 rail mounted components held securely in place during operation and easily removed for service.

- Brass Inserts are provided for TS35 DIN rails or mounting plate to be installed inside the enclosure.

- Captive, corrosion resistant stainless steel cover screws.

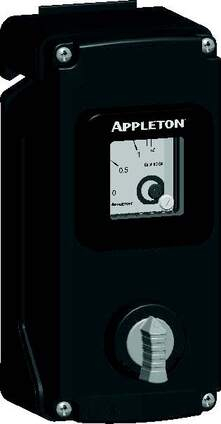

Standard Materials

- Body, cover, cable gland and blanking plug: polyamide,black finish

- Cover screws: stainless steel

- Optional nameplates: stainless steel

Accessories

- Key for changing actuator blocks.

- Guard for mushroom head actuator.

- Padlockable guard.

- M5 earth stud.

- Combination drain and breather available in brass, polyamide

and stainless steel.

ATEX Certifications and Compliances

- Certification Type PCe

— Gas: Zone 1 and 2

– Conforming to ATEX 94/9/CE: II 2 G

– Type of Protection: Ex de IIC/Ex demb IIC (depending of the actuator)

– Temperature Class: T6

— Dust: Zone 21 and 22

– Conforming to ATEX 94/9/CE: II2 D

– Type of Protection: Ex tD A21

— Surface Temperature: T75 °C (T167 °F)

— Ambient Temperature: -20 °C to +55 °C (-4 °F to +131 °F)

— CE Declaration of Conformity: 50221

— ATEX Certificate: LCIE 00 ATEX 6047

— Index of Protection according EN/IEC 60529: IP66

— Impact Resistance (shock): IK09

EURASEC Certification

- EURASEC RU C-FR 05.B.00911

Other Certification

- INMETRO Certificate: BVC 11.0640-X

Features

Increased safety

Options NOT INCLUDED - Nameplates: Lamacoid with different color combinations. - Padlocking ability at left, center, right or any position on selector switches. - Padlocking ability for momentary and maintained push buttons. - Special contact arrangements available, see Unicode 2 Series Customized Control Stations.